I posted a while ago about simplifying my control setup on my hydronic boiler. I have made those changes and in this post will walk through the improvements and drawbacks of my new approach.

The systems(3 installed) are all pretty basic on the hydronic end, they range from 1 to 3 zones. None of them are using mixing valves and i’m targeting a fluid temp of ~103F on the glycol side.

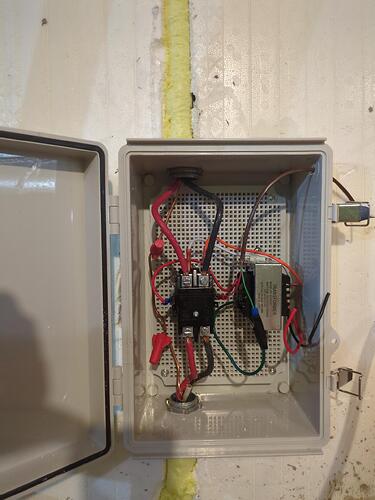

The “boilers” are Hashrate House tanks with S19jpros eqipped with Epic Control Boards. I have made a custom 24v contactor box to turn the whole tank on and off(Bang Bang) from a simple wall thermostat input.

So the order of operations is as follows: Client turns up wall thermostat > thermostat signals Contactor to turn on > Tank+miners turn on and begin hashing > once desired oil temp is reached the control board starts scaling the miners > when the space is heated the thermostat signals the contactor and power is cut to Tank/miners.

Pros:

Simple

Reliable

System is completely off and using no power when not in use

Native modulation seems more reliable than HA/server type modulation

Cons:

Bang Bang may not be good for miners long term

Control Boards maintain boiler/temp within a ~7F range which would be too broad for certain applications.

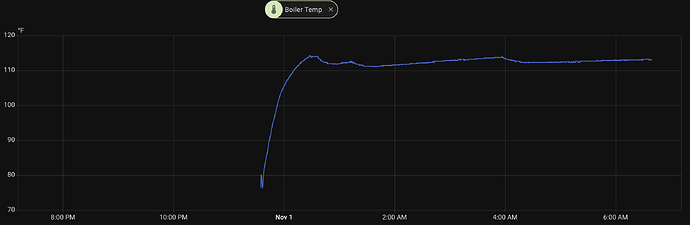

Here is an example of the boiler temp(oil side) being modulated over the course of a night of heating

The small bumps indicate when the miners are throttling down. Epic control boards are super fast to scale down and start hashing again.

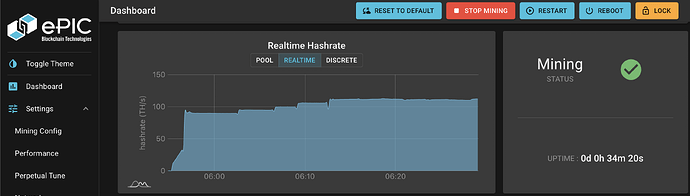

Here is a chart of the miner scaling up just after being turned on.

The miner completes 4 up scales in the course of 12 minutes

Overall I’m very happy with this setup, I haven’t had any calls from clients and the systems seems to work very well so far.

Let me know what you guys think!